7

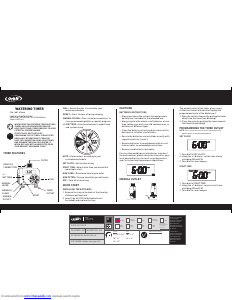

1. Select a Location

When choosing a location for your timer, consider the

following:

• Choose location near a power source (if hard wiring) or

electrical outlet (applicable only to U.S. retail timers)

• Ensure operating temperatures are not below 32° or

above 158° Fahrenheit (below 0° Celsius or above 70°

Celsius)

• Place it away from direct sunlight if possible

• Ensure at least 9” of space to the left of the sprinkler

timer box for the door to swing open after installation

• Locate the timer where there is easy access to sprinkler

wire (from valves). If mounted in an outdoor location,

shut the compartment door to keep the timer safe

from weather damage. To lock: insert the key and turn

clockwise to the locked position

Note: Sprinkler timers are weather-resistant to UL-50 and ETL

®

Listings, but should not be placed in areas where continuous

water could cause damage.

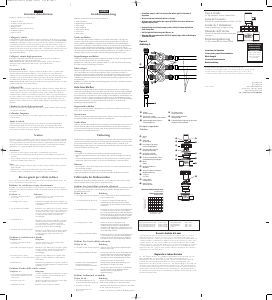

2. Mount the Timer

• Use the mounting template (included) to mark the

mounting screw location on the wall. See figure 1

• Install a No. 8 screw (included) into wall in the upper

template location. Leave the screw head protruding 1/8”

(3mm) from wall. Use expanding anchors (included) in

plaster or masonry, if necessary, for a secure hold

• Slip the timer over protruding screw (using keyhole slot

in back of timer). See figure 2

• Drive a No. 8 screw through one of the two pre-formed

holes located in lower back cabinet. See figure 2

3. Connect Valve Wires to Timer

• Strip 1/2” (12 mm) of the plastic insulation off the end of

each wire for both the timer wires and the valve wires

• Connect one wire from each valve (it doesn’t matter

which wire) to a single “Common” sprinkler wire (usually

white)

• Connect the remaining wire from each valve to a

separate colored sprinkler wire

See figure 3

Note: The maximum loading for each station/pump is 250mA,

the maximum loading for the timer is 500mA.

If the distance between the sprinkler timer and valves is under

700’ (210 m), use Orbit

®

sprinkler wire or 20 gauge (AWG) plastic

jacketed thermostat wire to connect the sprinkler timer to the

valves. If the distance is over 700’ (210 m), use 16 gauge (AWG) wire.

Important: All wires should be joined together using wire nuts,

solder, and/or vinyl tape. In wet environments like a valve box it

is recommended to use Orbit Grease Caps to prevent corrosion of

the connection and for protection from water infiltration.

Wiring Electric Valves

Strip 1/2” (12 mm) of plastic insulation off the end of each

individual wire. Each valve has two wires. One wire (it doesn’t

matter which one) is to be connected as the common. The

Figure 2: Hang timer on screw using keyhole

Figure 3:

Wiring Electric Valves

other valve wire is to be connected to the specific station wire

that will control that valve. The common wires for all the

valves can be connected together to one common wire going

to the controller. To avoid electrical hazards, only one valve

should be connected to each station. See figure 4

Important: The wire can be buried in the ground; however, for more

protection wires can be pulled through PVC pipe and buried under-

ground. Be careful to avoid burying the wires in locations where

they could bedamaged by digging or trenching in the future.

Your timer is equipped with the simple “push-in” terminals for

easy connection. Connect common wire to the common terminal.

Connect remaining wires to corresponding terminal locations.

ENGLISH

Praat mee over dit product

Laat hier weten wat jij vindt van de Orbit 91894 Besproeiingscomputer. Als je een vraag hebt, lees dan eerst zorgvuldig de handleiding door. Een handleiding aanvragen kan via ons contactformulier.