ONLINE MANUAL

Scan this QR Code with

your mobile device to take

you to the online manual.

Assembling The Upper Drum

Use assembly fasteners bag E.

1. Place the upper drum over

the rim of the lower drum,

making sure to align the

mounting holes in both

halves.

Note: Arrow labels have been

placed on the outside of the

drum as a reference for aligning

the two drum halves. The corresponding mounting holes must be

lined up to secure the mixing blades properly.

2. Place a spring washer and

then washer onto a M8x20

screw, then place this through

a threaded hole in the rim of

the upper drum.

3. Repeat Step 3 with the other

5 M8x20 screws around

the rim, then tighten all the

screws progressively until all 6 are secure.

4. Slide a rubber washer

between the inside of the

upper drum and one of the

mixing blades, making sure to

align all 3 holes. Then place

a M8x20 screw through this

assembly from the outside

of the drum. Slide a washer,

then a spring washer onto the

screw and fasten with a nut

on the inside.

5. Repeat Step 4 with the other mixing blade.

6. Tighten all of the xings on the mixing blades and ensure that

these are secure.

Adjusting the Drum Angle

WARNING! MAINTAIN A FIRM GRIP ON THE TIPPING

HANDLE WHILE TURNING THE HANDLE.

1. Disengage the locating pins

by pulling out on the control

handle away from the locking

plate to allow the drum to

rotate.

2. Rotate the drum to the

desired position by aligning

the locating pin with two of

the holes in the locking plate.

3. Engage the control handle

locating pins to secure the

position.

Note: The drum can be set at

dierent positions to cater for

mixing mortar and concrete,

emptying, or storing.

Starting & Stopping The Mixer

1. To start the mixer press the

green on “I” button.

2. To stop the mixer press the red o “O” button.

Assembling The Wheel Bracket

Note: It is recommended that 2 people assemble the cement mixer.

Use assembly fasteners bag A.

1. On one end of the wheel

bracket, insert a split pin into

the inner hole. Bend the ends

outwards so that the pin does

not fall out. Slide a washer

onto the shaft on the wheel

bracket, followed by a wheel

and then another washer.

Insert a second split pin into

the outer hole and deform the ends as well.

Note: The at face of the wheel should face outwards.

2. Repeat Step 1 for the other end of the wheel bracket and wheel.

Attaching The Support Leg & Wheel Bracket

Use assembly fasteners bag B.

1. Slide the support leg onto the

frame. Insert 2 M8x70 bolts

through the support leg and

frame, then place a washer

and spring washer onto each

bolt. Secure with the nuts

provided.

Note: Attach the support leg to the correct end of the frame. Refer to

the arrow labels on the frame for proper orientation.

2. Repeat Step 1 with the wheel

bracket on the other end of

the frame.

3. Tighten all the bolts and nuts securely.

Attaching The Locking Plate

Use assembly fasteners bag F.

1. Slide the locking plate over

the large diameter shaft at the

support leg end of the frame

assembly. The at face of the

plate should be facing out.

2. Slide a M8x25 bolt through

the locking plate, place a

washer and spring washer

onto the bolt, and then secure

it with a nut. Repeat with the

other bolt and hole in the

locking plate.

Attaching The Tipping Bar

Use assembly fasteners bag G.

1. Insert the metal disc and then

the spring into the sleeve

in the middle of the tipping

wheel. Holding the spring in

place with your nger, slide

the tipping wheel onto the

shaft in front of the locking

plate until the holes in the

tipping wheel bracket line up

with the holes on the shaft.

3. Slide a washer onto the

M10x65 bolt, and place

this through the holes in

the tipping wheel bracket

and shaft. Slide on another

washer and then secure this

with a nut.

Note: Do not over tighten the bolt and nut against each other as this

will prevent the wheel from pivoting about the bolt and allowing you to

control the tilt of the mixer drum.

Connecting The Motor

Use assembly fasteners bag H.

1. Slide the motor case over the

pinion shaft, making sure to

line the threaded stubs on the

case with the holes on the

frame.

2. Secure these stubs with the

washers and M8 nuts.

Unit Placement

The product may only be placed on a at surface. To provide added

stability screw the product to a concrete oor with the proper xation

materials including bolts, screws and washers.

WARNING! DO NOT PLACE ANY MATERIAL UNDER

THE PRODUCT TO ADJUST THE HEIGHT OR TO

ATTEMPT TO IMPROVE ITS STABILITY! IF THE

PRODUCT IS ON AN ANGLE AND/OR WOBBLY,

MOVE IT TO A DIFFERENT LOCATION. NEVER

OPERATE THE PRODUCT ON SOFT SURFACES

SUCH AS A LAWN OR GRAVEL SINCE IT COULD

SINK OR TIP OVER DURING OPERATION!

The Support Leg has two

mounting holes that can be used

to ensure sucient stability.

Use two screws or bolts (not

included, recommended size

M10 ) to secure it to a suitable

surface.

Drip Loop

To avoid the possibility of the

appliance plug or power point

getting wet, the user should

arrange a “drip loop” in the cord

connecting the cement mixer to

a wall mounted power point.

The “drip loop” is the part of the

cord that sits below the level

of the power point (or the connector if an extension cord is used). It

prevents water travelling along the cord and coming in contact with

the power point.

Attaching The Lower Drum

Use assembly fasteners bag C.

1. Slide the drive shaft bracket

onto the narrower shaft of the

lower drum. Use the ø42mm

rubber ring to hold the drive

shaft bracket in place.

2. With the help of a second

person, carefully set the lower

drum into the frame assembly

so that the shaft brackets slot

into the channels provided by

the frame.

Note: The larger diameter shaft

should be above the support leg.

3. Place a M8x65 bolt through

the hole in the frame, the

drive shaft bracket, a washer,

spring washer, and then

secure it with a nut.

4. Repeat Step 3 with the other side of the lower drum assembly.

Fastening The Mixing Blades

Use assembly fasteners bag D.

1. Slide a M8x20 screw through

the base of the drum from

the outside. Then place a

rubber washer on the screw,

followed by the mixing blade,

a washer, a spring washer,

and then fasten a nut loosely

onto the end of the screw.

Note: Ensure the mixing blades

are in the correct orientation. The

mixer blades cannot be secured

properly if the blades are upside

down. Do not tighten the screw

yet as it may make attaching the upper drum more dicult.

2. Repeat Step 1 with the other mixing blade.

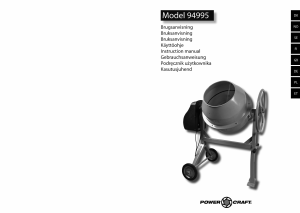

1. Tipping Handle

2. Locking Plate

3. Mixing Drum

4. Drive Shaft

5. Drive Shaft Bracket

6. On/O Switch

7. Motor Housing

8. Transport Wheels

9. Steel Frame

10. Support Leg

11. Transport Handle

CEMENT MIXER

KNOW YOUR PRODUCT

CMX-120

1. FRAME ASSEMBLY

5. CEMENT MIXER SETUP 6. USAGE3. TIPPING HANDLE ASSEMBLY 4. MOTOR ASSEMBLY2. DRUM ASSEMBLY

SETUP & PREPARATION OPERATION

ON

OFF

Mortar

Concrete

Unload

Storage

ON

OFF

Mortar

Concrete

Unload

Storage

ON

OFF

Mortar

Concrete

Unload

Storage

Mortar

Unload

Concrete

Storage

x 4

A

x 4

B M8x70

D

x 2M8x20

C

x 1ø42mm

x 2M8x65

x 6M8x20

x 2M8x20

E

x 1

x 1M10x65

G

F

x 2M8x25

H

x 4M8 Nut

x 4

A

x 4

B M8x70

D

x 2M8x20

C

x 1ø42mm

x 2M8x65

x 6M8x20

x 2M8x20

E

x 1

x 1M10x65

G

F

x 2M8x25

H

x 4M8 Nut

x 4

A

x 4

B M8x70

D

x 2M8x20

C

x 1ø42mm

x 2M8x65

x 6M8x20

x 2M8x20

E

x 1

x 1M10x65

G

F

x 2M8x25

H

x 4M8 Nut

x 4

A

x 4

B M8x70

D

x 2M8x20

C

x 1ø42mm

x 2M8x65

x 6M8x20

x 2M8x20

E

x 1

x 1M10x65

G

F

x 2M8x25

H

x 4M8 Nut

x 4

A

x 4

B M8x70

D

x 2M8x20

C

x 1ø42mm

x 2M8x65

x 6M8x20

x 2M8x20

E

x 1

x 1M10x65

G

F

x 2M8x25

H

x 4M8 Nut

x 4

A

x 4

B M8x70

D

x 2M8x20

C

x 1ø42mm

x 2M8x65

x 6M8x20

x 2M8x20

E

x 1

x 1M10x65

G

F

x 2M8x25

H

x 4M8 Nut

x 4

A

x 4

B M8x70

D

x 2M8x20

C

x 1ø42mm

x 2M8x65

x 6M8x20

x 2M8x20

E

x 1

x 1M10x65

G

F

x 2M8x25

H

x 4M8 Nut

x 4

A

x 4

B M8x70

D

x 2M8x20

C

x 1ø42mm

x 2M8x65

x 6M8x20

x 2M8x20

E

x 1

x 1M10x65

G

F

x 2M8x25

H

x 4M8 Nut

1

2

3

4

5

6

8

7

9

10

11

WARNING! ENSURE THE TOOL IS SWITCHED OFF

AND DISCONNECTED FROM THE POWER SUPPLY

BEFORE PERFORMING ANY OF THE FOLLOWING

OPERATIONS.

WARNING! TO REDUCE THE RISK OF ELECTRICAL

SHOCK, THE USE OF A RESIDUAL CURRENT

DEVICE (RATED 30MA OR LESS) IS RECOMMENDED.

Praat mee over dit product

Laat hier weten wat jij vindt van de Ozito CMX-120 Cementmixer. Als je een vraag hebt, lees dan eerst zorgvuldig de handleiding door. Een handleiding aanvragen kan via ons contactformulier.

beantwoord | Ik vind dit nuttig (0) (Vertaald door Google)