WARNING! When using mains-powered tools, basic safety precautions, including

the following, should always be followed to reduce risk of re, electric shock, personal

injury and material damage.

Read the whole manual carefully and make sure you know how to switch the tool o in an emergency,

before operating the tool.

Save these instructions and other documents supplied with this tool for future reference.

The electric motor has been designed for 240V only. Always check that the power supply corresponds to

the voltage on the rating plate.

Note: The supply of 230V and 240V on Ozito tools are interchangeable for Australia and New Zealand.

This tool is double insulated; therefore no earth wire is required.

Note: Double insulation does not take the place of normal safety precautions when operating

this tool. The insulation system is for added protection against injury resulting from a possible

electrical insulation failure within the tool.

If the supply cord is damaged, it must be replaced by an electrician or a power tool repairer in order to

avoid a hazard.

Using an Extension Lead

Always use an approved extension lead suitable for the power input of this tool. Before use, inspect the

extension lead for signs of damage, wear and ageing. Replace the extension lead if damaged or defective.

When using an extension lead on a reel, always unwind the lead completely. Use of an extension lead

not suitable for the power input of the tool or which is damaged or defective may result in a risk of re and

electric shock.

The power outlet for the compressor is recommended to be protected by a 30amp residual current device

Operating Tips

For best loading results, proceed as follows:

• Add the required amount of stone into the drum.

• Add the required amount of sand into the drum.

• Add the required amount of cement into the drum.

• Pour the required amount of water into the drum.

WARNING!

1. DO NOT LET THE SHOVEL MOUTH OR ANY

OTHER DEVICE ENTER THE DRUM MOUTH

DURING LOADING.

2. NEVER PLACE HANDS INSIDE THE REVOLVING

DRUM OR NEAR ANY ROTATING PARTS.

3. PLACE THE CEMENT MIXER AS CLOSE AS

POSSIBLE TO THE WORK SITE. DO NOT MOVE

THE CEMENT MIXER WHEN LOADED.

4. RE-TIGHTEN ALL BOLTS ATTACHING MOTOR AND

MOTOR HOUSING ASSEMBLY, DRUM ASSEMBLY

& FRAME ASSEMBLY AFTER FIRST MIX.

Note: When measuring out cement and ballast (or sharp sand/

gravel), use a small bucket to ensure accurate ratios of cement:

ballast. Refer to the instructions that come with your cement.

Ensure your chosen quantity of concrete is large enough that the

cement mixer will function and small enough that it will t in the

drum, see load sizes in specications section of manual to calculate

quantities.

When the mixture is the right consistency to use, empty the drum.

Pour the mixed cement by releasing the tipping handle and rotating

the drum to the empty position while the machine is running. Be sure

to pour the mix slowly and smoothly to avoid tilting the cement mixer.

• When the drum is empty, turn the cement mixer o.

WARNING! DO NOT TURN THE MIXER OFF WHILE

THERE IS MATERIAL IN THE DRUM UNLESS THE

DRUM IS OVERLOADED & EXCESS MATERIAL

NEEDS TO BE REMOVED FOR PROPER OPERATION

OF THE MIXER.

DURING STANDARD OPERATION, THE DRUM

SHOULD BE UNLOADED WHILE IT IS STILL ON &

ROTATING.

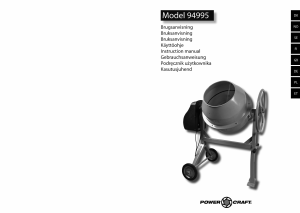

CEMENT

MIXER

120L 550W

INSTRUCTION MANUAL

SPECIFICATIONS

Motor: 550W, 0.7HP

Input Power: 240V ~ 50Hz

No Load Speed: 2,800/min

Drum Speed: 29.5/min

Gross Drum Volume: 120L

Mixed Wet Volume: 91L

Drum Mouth: ø385mm

IP Rating: IP44

Weight: 46.5kg

CMX-120

STANDARD EQUIPMENT

IN ORDER TO MAKE A CLAIM UNDER THIS

WARRANTY YOU MUST RETURN THE PRODUCT

TO YOUR NEAREST BUNNINGS WAREHOUSE WITH

YOUR BUNNINGS REGISTER RECEIPT. PRIOR TO

RETURNING YOUR PRODUCT FOR WARRANTY

PLEASE TELEPHONE OUR CUSTOMER SERVICE

HELPLINE:

Australia 1800 069 486

New Zealand 0508 069 486

3 YEAR REPLACEMENT WARRANTY

Your product is guaranteed for a period of 36 months from

the original date of purchase. If a product is defective it will

be replaced in accordance with the terms of this warranty.

Warranty excludes consumable parts, for example: valve adapters

and accessories.

WARNING

The following actions will result in the warranty being void.

• If the tool has been operated on a supply voltage other

than that specified on the tool.

• If the tool shows signs of damage or defects caused

by or resulting from abuse, accidents or alterations.

• Failure to perform maintenance as set out within the

instruction manual.

• If the tool is disassembled or tampered with in any way.

• Professional, industrial or high frequency use.

WARRANTY

TO ENSURE A SPEEDY RESPONSE PLEASE

HAVE THE MODEL NUMBER AND DATE OF

PURCHASE AVAILABLE. A CUSTOMER SERVICE

REPRESENTATIVE WILL TAKE YOUR CALL

AND ANSWER ANY QUESTIONS YOU MAY

HAVE RELATING TO THE WARRANTY POLICY

OR PROCEDURE.

OZITO

Australia/New Zealand (Head Office) 1-23 Letcon Drive, Bangholme, Victoria, Australia 3175.

The benefits provided under this warranty are in addition

to other rights and remedies which are available to you at law.

Our goods come with guarantees that cannot be excluded

at law. You are entitled to a replacement or refund for a major

failure and for compensation for any other reasonably foreseeable

loss or damage. You are also entitled to have the goods repaired

or replaced if the goods fail to be of acceptable quality and the

failure does not amount to a major failure.

Generally you will be responsible for all costs associated with

a claim under this warranty, however, where you have suffered

any additional direct loss as a result of a defective product you

may be able to claim such expenses by contacting our customer

service helpline above.

ozito.com.au

Cement Mixer

1118

x 4

A

x 4

B M8x70

D

x 2M8x20

C

x 1ø42mm

x 2M8x65

x 6M8x20

x 2M8x20

E

x 1

x 1M10x65

G

F

x 2M8x25

H

x 4M8 Nut

Assembly Fasteners

ELECTRICAL SAFETY

The appliance is not to be used by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction.

Young children should be supervised to ensure that they do not play with the appliance.

WARNING! For your own safety, do not try to use your cement mixer or plug it in until it is

completely assembled and installed according to the instructions and until you have read and

understood the following:

• Avoid dangerous conditions. Do not use the mixer in wet or damp areas or expose it to rain. Do not use it

in areas where fumes from paint, solvents or ammable liquids pose a potential hazard.

• Inspect your cement mixer. Check your cement mixer before turning it on. Keep guards in place and in

working order. Form a habit of checking to see that keys and adjusting wrenches are removed from the

cement mixer area before turning on. Replace damaged, missing or failed parts before using it.

• Wear protective gear. Foreign objects may be thrown from the cement mixer while in operation. This can

cause facial injuries. Always wear safety goggles and/or face shields.

• Do not touch the rotating drum during operation. Keep limbs, hair and objects clear of moving parts.

• Never leave cement mixer running unattended. Don’t leave cement mixer until it has come to a complete

stop.

• Disconnect power. Unplug when not in use, before making adjustments, changing parts, cleaning, or

working on the mixer.

• Maintain your cement mixer with care. Clean the cement mixer immediately after use. Keep the cement

mixer clean for best and safest performance.

• Moving the cement mixer. Do not tow the cement mixer by using a vehicle. Use an approved trailer to

move the cement mixer if it is to be transported.

• Drugs, alcohol and medication. Do not operate the mixer while under the inuence of drugs, alcohol, or

any medication that could aect your ability to use it properly.

CEMENT MIXER SAFETY WARNINGS

GENERAL POWER TOOL SAFETY WARNINGS

WARNING! Read all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference. The term “power tool” in the warnings

refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b. Do not operate power tools in explosive atmospheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while operating a power tool. Distractions can cause you to

lose control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tools. Unmodied plugs and matching outlets will

reduce risk of electric shock.

b. Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

d. Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase

the risk of electric shock.

e. When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use common sense when operating a power tool. Do

not use a power tool while you are tired or under the inuence of drugs, alcohol or medication. A

moment of inattention while operating power tools may result in serious personal injury.

b. Use personal protective equipment. Always wear eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce

personal injuries.

c. Prevent unintentional starting. Ensure the switch is in the o-position before connecting to

power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your

nger on the switch or energising power tools that have the switch on invites accidents.

d. Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

e. Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away

from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g. If devices are provided for the connection of dust extraction and collection facilities, ensure

these are connected and properly used. Use of dust collection can reduce dust-related hazards.

h. Do not let familiarity gained from frequent use of tools allow you to become complacent and

ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

4. Power tool use and care

a. Do not force the power tool. Use the correct power tool for your application. The correct power

tool will do the job better and safer at the rate for which it was designed.

b. Do not use the power tool if the switch does not turn it on and o. Any power tool that cannot be

controlled with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or the battery pack from the power tool before

making any adjustments, changing accessories, or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool. Power tools are dangerous in the hands

of untrained users.

e. Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts and any

other condition that may aect the power tool’s operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking

into account the working conditions and the work to be performed. Use of the power tool for

operations dierent from those intended could result in a hazardous situation.

h. Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

5. Service

a. Have your power tool serviced by a qualied repair person using only identical replacement

parts. This will ensure that the safety of the power tool is maintained.

5. TROUBLESHOOTING 6. APPLIANCE CARE7. LOADING THE DRUM

MAINTENANCE DESCRIPTION OF SYMBOLS

Cleaning

• Wipe o any external material on the motor cover. Do not use

petrol, turpentine, lacquer, paint thinner, dry cleaning uids or

similar products.

• The use of chemical products or solvents may damage the motor

cover.

• Thoroughly clean your cement mixer at the end of each days

operation. Keep your cement mixer clean. The slightest trace of

material left in the drum assembly will harden and attract more

material each time the machine is used.

• Dried cement should be scraped out of the drum assembly.

• DO NOT throw bricks into the drum assembly to clean it out.

• DO NOT beat on the drum with a shovel, hammer or other tools to

break up accumulation of dried cement mix as the cement mixer

may be damaged.

• The drum may be scoured for approximately 2 minutes, using a

1” stone and water mixture. After this, discharge the stone/water

mixture and hose down the drum assembly inside and out.

• The IP44 protection clad construction of the mixer enables the

DRUM ASSEMBLY ONLY to be hosed down safely. Avoid getting

water on the motor and motor housing, DO NOT wet the motor

and motor housing.

General Maintenance

• Ball bearings are packed with grease at the factory. No further

lubrication of bearings is required.

• During normal use, painted surfaces can lose their coating during

the mixing process. Wipe all exposed surfaces regularly with an

oily rag to prevent corrosion.

Note: Loss of paint and rust are not covered under warranty.

• Keep air vents clean of dust and dirt.

• Remove dust and dirt from the cement mixer regularly with soft

cloth, brush or compressed air. Use a mild detergent and a soft

cloth to clean plastic parts.

• If the power cord is damaged, have it replaced by an electrician or

a power tool repairer.

• Regularly check that all bolts, screws and nuts are securely xed

as these could work loose during normal operation.

• Do not open the motor cover under any circumstances.

Note: Ozito Industries will not be responsible for any damage or

injuries caused by the repair of the tool by an unauthorised person or

by mishandling of the tool.

WARNING! ENSURE THE TOOL IS SWITCHED OFF

& DISCONNECTED FROM THE POWER SUPPLY

BEFORE PERFORMING ANY OF THE FOLLOWING

MAINTENANCE PROCEDURES.

WARNING! ALWAYS START THE CEMENT MIXER

BEFORE LOADING THE DRUM. LOAD THE DRUM

WHILE IT IS ROTATING.

WARNING! DO NOT POUR OR SPRAY WATER

DIRECTLY INTO OR OVER THE MOTOR COVER.

WARNING! ENSURE THE MATERIAL IS NOT LOADED

INTO THE MIXER ALL AT ONCE. ADD THE MATERIAL

STEADILY OVER THE MIXING BLADES, THIS HELPS

PREVENT THE MATERIAL FROM STICKING TO THE

BACK OF THE DRUM.

Symptom Possible Cause Suggested Solution

The cement mixer

does not start

Not connected to

mains power.

Connect to mains power.

Power cord or plug is

defective.

Contact Ozito Customer

Service.

Other electrical

defect in the product.

Contact Ozito Customer

Service.

Cement mixer does

not reach full power

Extension cord not

suitable for operation

with this product.

Use a heavy duty

extension cord, <25m.

Power source (eg. a

generator) has too

low a voltage.

Connect to another power

source.

Mixing volume is too

large.

Reduce the amount of

material in the drum.

Excessive vibration

or noise

Mixer blades are dull/

damaged.

Replace with new ones

via Ozito Spare Parts.

Bolts/nuts are loose. Tighten bolts/nuts.

Double insulated

Danger of electric shock

Power tools that are no longer usable should not be

disposed of with household waste but in an environmentally

friendly way. Please recycle where facilities exist. Check

with your local council authority for recycling advice.

Recycling packaging reduces the need for landll and raw

materials. Reuse of recycled material decreases pollution in

the environment. Please recycle packaging where facilities

exist. Check with your local council authority for recycling

advice.

CARING FOR THE ENVIRONMENT

SPARE PARTS

Spare parts can be ordered from the Special Orders Desk

at your local Bunnings Warehouse.

For further information, or any parts not listed here, visit

www.ozito.com.au or contact Ozito Customer Service:

Australia 1800 069 486

New Zealand 0508 069 486

Praat mee over dit product

Laat hier weten wat jij vindt van de Ozito CMX-120 Cementmixer. Als je een vraag hebt, lees dan eerst zorgvuldig de handleiding door. Een handleiding aanvragen kan via ons contactformulier.

beantwoord | Ik vind dit nuttig (0) (Vertaald door Google)